Aquaculture by Design

Can oyster aquaculture help make the Chesapeake Bay cleaner, faster?

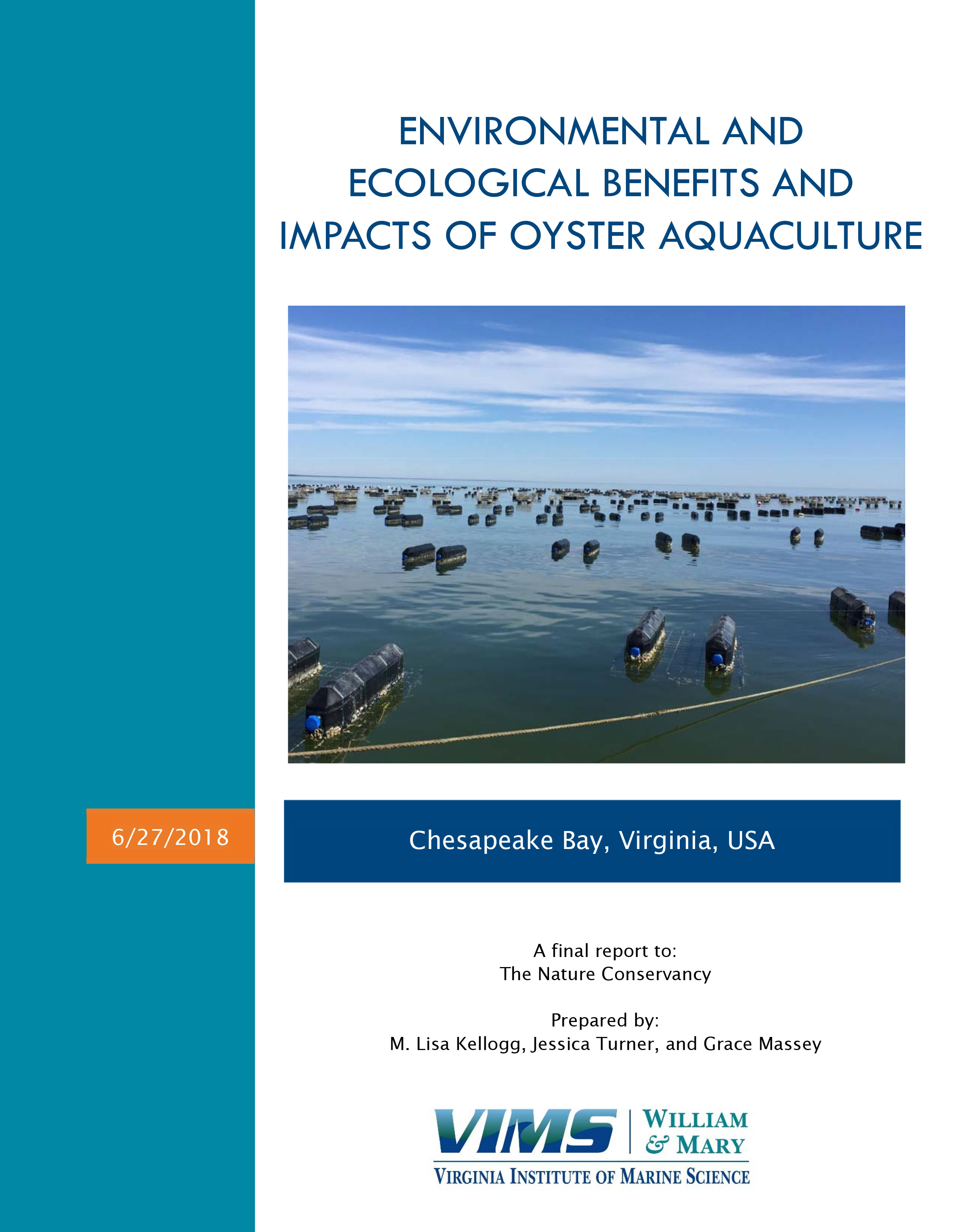

The Nature Conservancy’s oyster restoration efforts in the Chesapeake Bay have primarily focused on supporting wild oyster populations, but the Bay’s oyster aquaculture industry is the largest on the East Coast, providing sustainable seafood and green jobs. There is some evidence that it can have positive impacts on the ecosystem—but those impacts have never been fully quantified.

To develop a better understanding of the specific connections between oyster aquaculture, water quality and ecosystem health, TNC partnered with the Virginia Institute of Marine Science (VIMS) and four oyster growers to answer the question:

Can oyster aquaculture make the Bay cleaner, faster?

The Study

Wild oyster populations in the Chesapeake Bay have declined to less than 1% of their historical numbers. With that decline, the Bay has lost the oysters’ capacity to filter sediment and algae and remove nitrogen and phosphorus—harmful pollutants in excess—from the water.

We worked with VIMS and four oyster growers—Big Island Aquaculture, Chapel Creek Oyster Company, Lynnhaven Oyster Company and White Stone Oyster Company—on this two-year study. The growers graciously allowed us to work in and around their operations as we collected data to quantify aquaculture's influence on water quality and ecosystem health.

After sampling and studying environmental variables at each of the four oyster farms including water currents, water clarity and chemistry and sediment type (and the creatures that live in it), our research indicates that oyster aquaculture is a low impact way of producing animal protein.

The data indicate that the oyster aquaculture industry can help to restore water quality in our rivers and bays. For every 100,000 oysters grown and harvested annually, six pounds of nitrogen and phosphorus pollution are removed from the Bay. Oyster farms may also reduce wave energy and help protect vulnerable shorelines.

As oyster aquaculture grows, so will the food and water quality benefits to the Chesapeake Bay.

Download the final aqualcuture study report and addendum.

The Growers

Click on the map points below to learn more about the growers who participated in our study.

_1640x1230.jpg?crop=205%2C0%2C1230%2C1230&wid=270&hei=270&scl=4.555555555555555)

The Growers The Virginia oyster farmers who participated in our study.

Big Island Aquaculture

Bruce Vogt and his son Daniel started Big island Oyster Company in Guinea, Virginia in 2011. They are located in the extensive marshes near the mouth of the York River and grow their oysters in floating bags. Daniel keeps a close eye on the oysters as they grow, occasionally moving them around their grounds to compensate for varying growth rates.

Bruce and Daniel have noticed what they feel is an increase in both the number of species and the quantity of fish in the area since they began their operation.

Chapel Creek Oyster Company

Trey Sowers has been farming oysters on the Piankatank River since 2011. His company, Chapel Creek Oyster Company, grows the oysters in cages that sit on the bottom of the river. Trey uses a winch on his boat to haul the cages off the bottom and onto the boat where he can sort through the oysters.

Trey has seen changes in the area where his cages are over time including more underwater grasses and more fish. He hopes that by working with TNC on this project, the findings will confirm his belief that the area is getting healthier (note: this study did not measure submerged aquatic vegetation impacts).

Lynnhaven Oyster Company

Lynnhaven Oyster Company is a grower for Cherrystone Aqua-Farms. Owner Norman "Hap" Chalmers started farming oysters as a hobby which then grew into a business. They grow their oysters using a bottom cage system in the Lynnhaven River near the mouth of the Chesapeake Bay.

White Stone Oyster Company

The Whites Stone Oyster Company, located in White Stone, VA, was started in 2013 by Tom Perry. White Stone uses a floating rack system where the oysters are contained in mesh bags that are secured to the racks. Most of these racks are located in the Chesapeake Bay just off of Windmill Point.

After the oysters are harvested, they are processed and sorted at the company's facility on Antipoison Creek in White Stone, and then bagged for shipment to restaurants around the Bay region.

Tom hopes that by working with TNChe will gain additional information about the area where he grows his oysters which will allow his operation to be more productive.

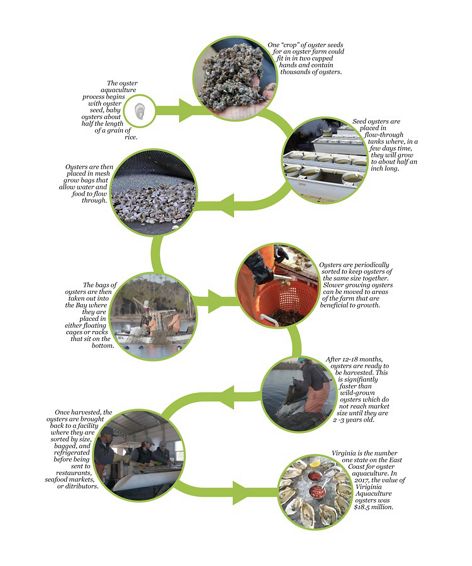

Aquaculture 101

There are two general types of oyster aquaculture—intensive and extensive.

Intensive aquaculture involves growing oysters in bags and cages either floating in the water or secured just above the bottom. The oysters are routinely checked and sorted until they grow to market size in one to two years.

Intensive aquaculture typically uses seed oysters which are small, unattached baby oysters. This method produces more uniform and high quality oysters which are ideal for the half shell market.

Extensive aquaculture involves placing young oysters on existing natural or man-made reefs and then later harvesting them within two years.

In some cases, extensive aquaculture uses spat on shell oysters which are baby oysters (spat) attached to recycled oyster shell, also know as "cultch". With spat on shell oysters, there are usually several spat attached to each shell. Most of the oysters produced by extensive aquaculture are for the shucked oyster market.

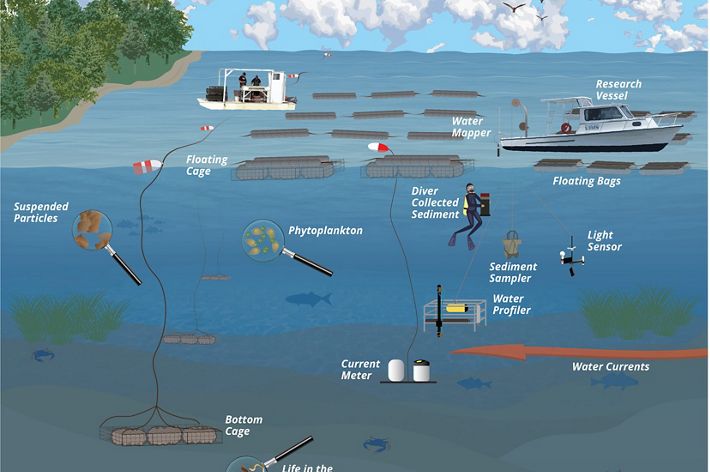

Gathering Data

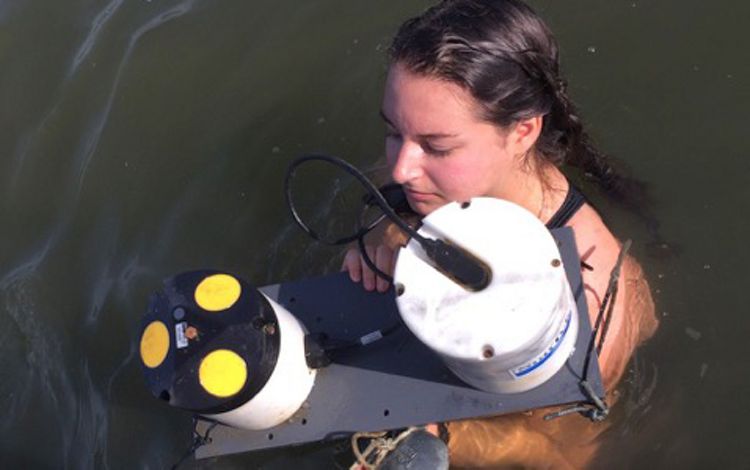

TNC and VIMS collected a large suite of data to measure environmental variables at each of the four oyster farms including water currents, water clarity and chemistry, and sediment type and the creatures that live in it.

Get more details in the diagram and gallery below.

More Details about the Study Methods:

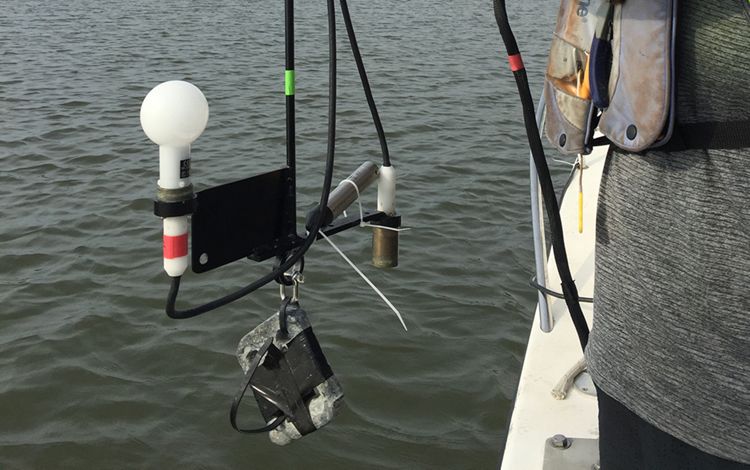

Water Quality Mapper: Attached to the side of the research vessel is a water quality sensor that samples the water every 10 seconds as the boat moves through the oyster farm.

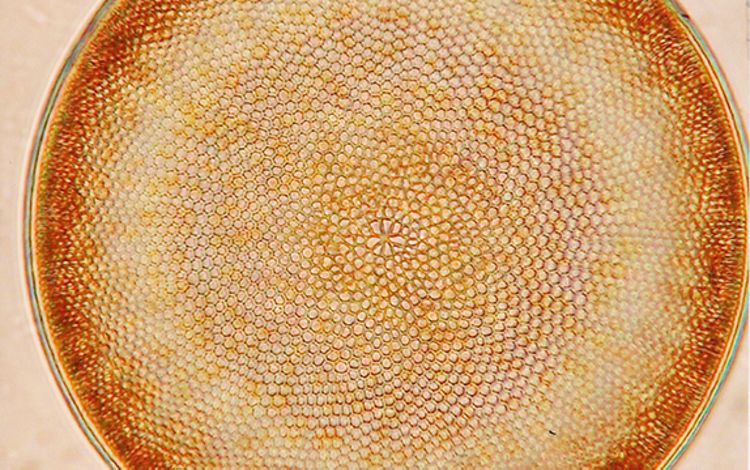

It measures parameters such as dissolved oxygen, water temperature, salinity and chlorophyll. Chlorophyll is a plant pigment that is used to determine the amount of phytoplankton in the water.

Using this system, scientists can generate a picture of water quality around the entire oyster farm and possibly see what, if any, impact the oyster farm is having.

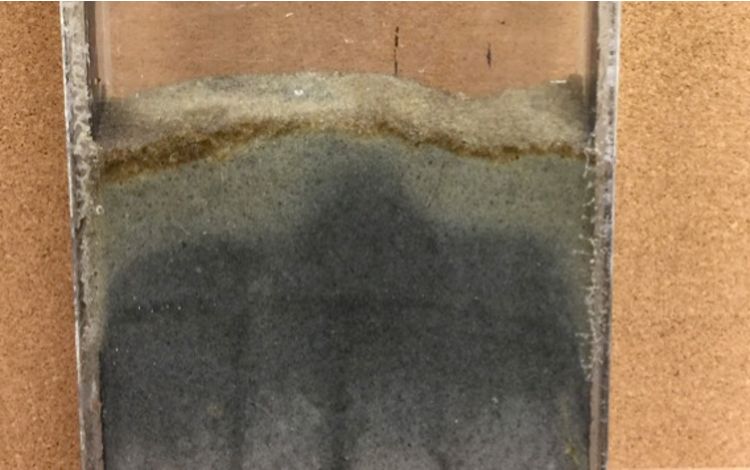

Suspended Particles: In the Chesapeake Bay, sediment and plankton can stick together to form larger particles that both absorb and scatter sunlight as it shines through the water—meaning there is less light available for underwater grasses.

Oysters filter these particles; some of the particles are absorbed into oyster tissue and shell, while some are excreted and deposited on the bottom.